- Home

- Wet Wipes Machines

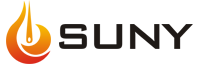

- Automatic Canister Filling Wet Wipes Machine

Wet Wipes Machine Details

Automatic Canister Filling Wet Wipes Machine

Capacity: 3600 bottel/min

Final Products: Barrel Tub/Canister Wet Wipes

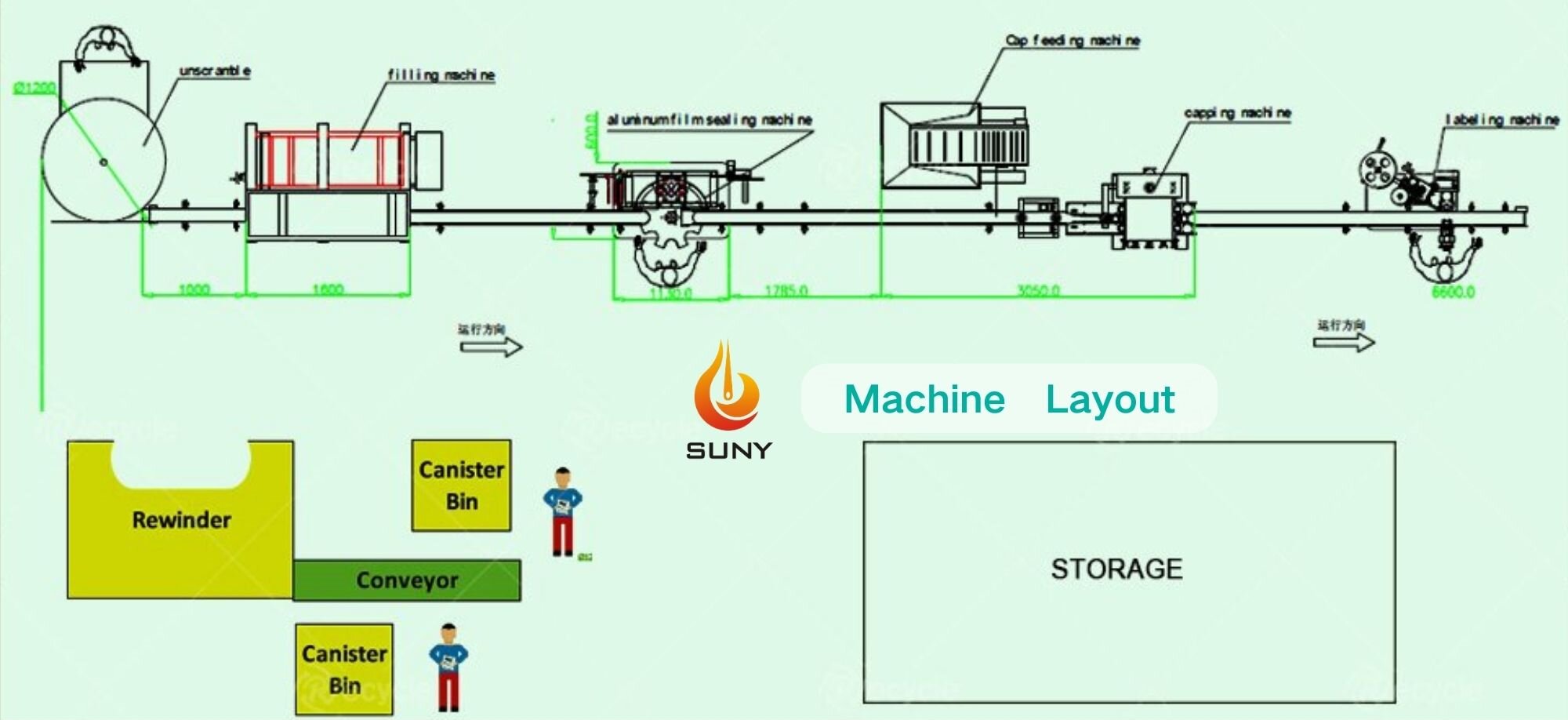

The fully automatic bucket wet wipes production line is efficient and fully automated equipment for the integrated production from nonwoven cutting, liquid filling, and capping to labeling, which is suitable for the production of disinfectant wet wipes, alcohol wipes, and other bucket wet wipes products to meet the different specifications and production capacity requirements.

SEND PHONE: +8619903886476

SEND EMAIL: wipemachinery@gmail.com

Equipment Advantages:

- Efficient production capacity: equipment capacity up to 3600 bottles / minute, to meet the needs of large-scale production.

- Support customization: Adapt to the production of wipes in drums of different diameters and heights, with high flexibility.

- Precise liquid filling system: Equipped with quantitative liquid filling function to ensure uniform liquid distribution.

- Fully automated operation: the whole process is automated from nonwoven cutting to finished product output.

- High-quality sealing: automatic heat sealing device to ensure long-lasting moisturizing and sealing of wipes.

- Labeling function: support automatic labeling to enhance the consistency and professionalism of product appearance.

- Multi-functional design: Equipped with multi-functional modules such as cutting, rewinding, liquid addition and sealing.

Product Description

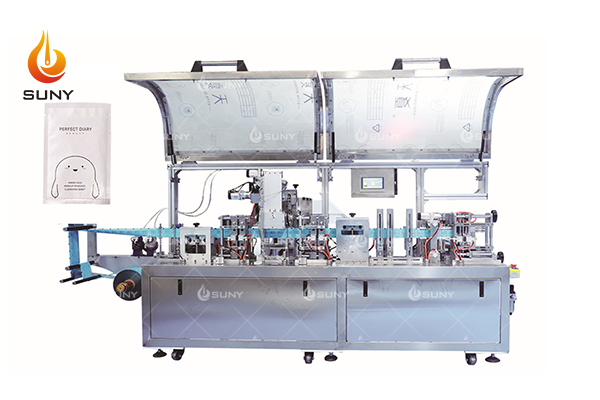

A fully automatic canned wet wipes production line is a set of highly intelligent and fully automated equipment, designed to meet the demand for efficient and mass production of bucket wet wipes. The equipment integrates the traditional cumbersome production process into an integrated operation through automation technology, covering the entire process from nonwoven cutting to liquid filling, capping, labeling, and finished product output, which greatly improves production efficiency and reduces manual intervention while ensuring the consistency of the products and hygiene standards.

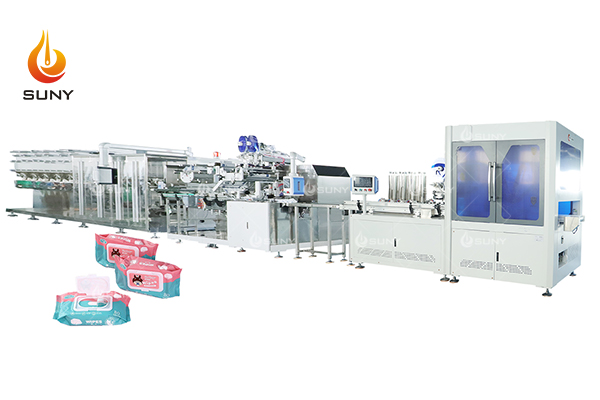

The equipment is capable of processing large rolls of nonwovens starting with a slitting and rewinding device that cuts the large rolls of fabric into smaller rolls and accurately controls the cutting width and length to ensure compliance with product specifications. Subsequently, the small rolls of fabric are manually loaded into the drum and enter the fully automatic assembly line operation. The liquid filling section adopts a high-precision quantitative filling device, which accurately injects cleaning liquid, alcohol, or disinfectant according to the preset parameters to ensure that the liquid content of each bucket of wipes is consistent and uniform. Next, the equipment completes the film sealing of the top of the bucket through heat sealing technology, and then the automated robotic arm completes the installation and locking of the bucket lid to ensure strong sealing and high product quality.

After sealing, the finished pail enters the labeling process, where each pail is labeled with brand information, instructions for use, and production date through an automatic labeling system, with precise and smooth labeling position, without manual adjustment. Finally, the barrels of wet wipes are orderly output through the conveyor device, directly into the packaging or storage stage. The equipment is highly adaptable and can flexibly cope with different diameters and heights of bucket designs, supporting diversified product customization.

The whole production line is operated by an advanced PLC intelligent control system, users can easily complete the production parameter setting and real-time monitoring through the touch screen. The equipment has an automatic alarm function, when there is an abnormality in the operation, the system will promptly prompt and automatically shut down to ensure a safe and stable production environment. The equipment is made of high-strength stainless steel, which is corrosion-resistant and easy to clean, and also meets the food-grade hygiene standards, which is especially suitable for the production of sanitized wet wipes and other products with high hygienic requirements.

Fully automatic bucket wet wipes production line can not only adapt to large-scale industrialized production but also can quickly switch specifications to meet different market demands. Its high efficiency, precision, and hygienic features make it an ideal choice for bucket-wet wipes manufacturers to improve production capacity and optimize quality. This equipment is widely used in daily chemical enterprises, cleaning products manufacturers, and medical and health care fields, and is the necessary equipment to realize intelligent and efficient production.

Wet Wipes Type

The automatic bucket wipes production line can produce many types of bucket wipes, including cleaning wipes, disinfecting wipes, alcohol wipes, baby wipes, kitchen wipes, car cleaning wipes and industrial wipes. The equipment completes the production through fully automated processes such as nonwoven cutting, liquid filling, capping, labeling, and finished product output, and supports a variety of liquid formulas and adapts to different bucket specifications. The products are suitable for daily cleaning, medical disinfection, baby care, industrial cleaning and other scenarios, with high production efficiency and stable quality, which is the ideal equipment to meet the diversified market demand.

Barrel Tub/Canister Wet Wipes

Barrel Tub/Canister Wet Wipes

Barrel Tub/Canister Wet Wipes

Barrel Tub/Canister Wet Wipes

| Equipment Name | Automatic Canister Filling Wet Wipes Machine |

| Production Capacity | 3600 bottel/min |

| Bottel Size | About 95mm(CUSTOMIZED) |

| Sealing Material | Rolled Film |

| Power | 380V 50HZ |

| Motor Power | 1.0Kw |

| Size | About 4200*1100*2200MM |

| Weight | 1000kg |

| Control system | PLC control, touch screen operation |

| Support Language | Chinese, English, French (can be customized) |

| Material | Spunlace non-woven fabric |

| Packing Material | Aluminized film, aluminum foil film, PE/PP, PO/PPE |

| Packing Film Material | PET/PE,PETIAL/PE,PET/AL/CPP,PAPER/AL/PE,Film thickness:0.07mm-0.09mm |

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

Explore our FAQ page for quick answers to commonly asked questions about our services, project assistance, or general guidance.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: wipemachinery@gmail.com

Whatsapp: +86 19903886476