Why Spunlace Non-Woven Fabric is Used in Wet Wipe Production

December 9, 2024What is Spunlace Non-Woven Fabric?

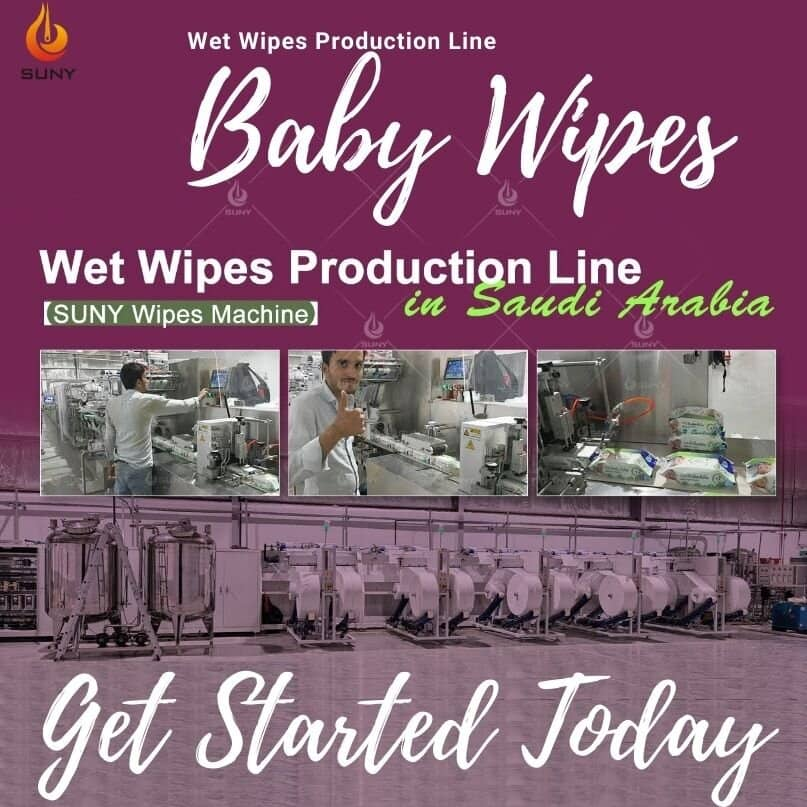

The Spunlace process is a nonwoven manufacturing system. It uses jets of water to entangle fibers, ensuring fabric integrity. It is a type of fabric within the non-woven category based on its specific manufacturing technique and can be a composite of different fibers.

Typical Fiber Types in Spun-Lace for Wet Wipes

Common fiber types in wet wipes and their properties include:

Polyester (PET) & Polypropylene (PP): These fibers contribute to certain characteristics of the wet wipe.

Viscose (Rayon in the USA) & Tencel: They have their unique properties.

Wood pulp: An important component.

Cotton: Adds specific qualities.

The most common fiber combination for spun-lace in wet wipe applications is PET + VISCOSE. Currently, with the development of spunlaced nonwoven technology, new spunlaced technologies have emerged to produce Woodpulp Spunlace Fabric. There are two types: Woodpulp + PET and Woodpulp + PP. This wood pulp non-woven fabric is a more economical alternative substrate for spun-lace wipers. It is rare to find a wet wipe made of only one fiber. Fibers are blended in different ratios according to specific requirements. For example, a household wet wipe may require more absorbency and strength rather than just softness. Cost is also a significant factor. Fibers like cotton, viscose, and Tencel can be costly, so the fiber blend is adjusted based on the product and its application. Through incorporating appropriate properties, innovative products and solutions can be created to solve problems and meet various needs, achieving a balance between product use life and cost. (The properties of different fibers can be seen in the following table.)

Pattern Types for Spun-Lace

There are three patterns commonly used in spun-lace fabric for wet wipes: Plain, Pearl (Embossed), and Mesh type. The plain pattern is more common and widely accepted in the wipes market. The choice of pattern depends on consumer preferences. Although the pearl embossed pattern makes the wipes look more attractive, it also increases the cost.

Contact Tel: +86 199 0388 6476

Contact Email: wipemachinery@gmail.com