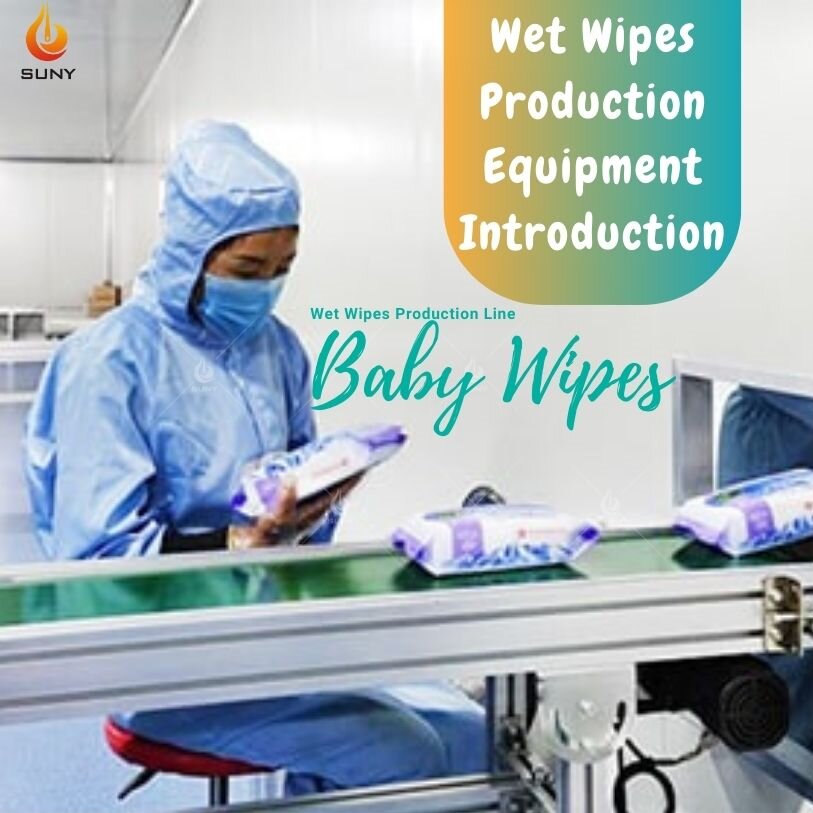

Wet Wipes Production Equipment Introduction

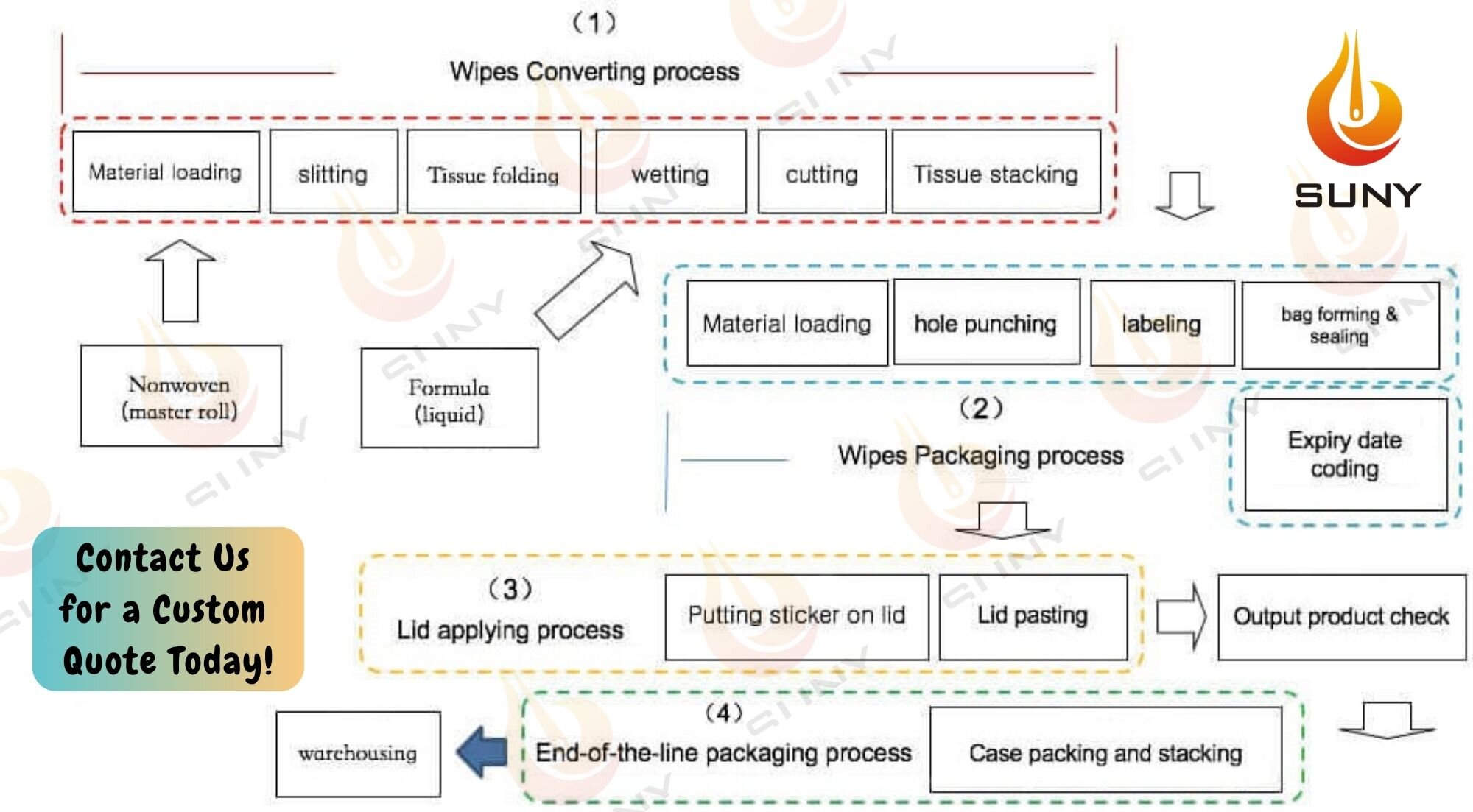

February 11, 2025To understand the machines required for producing market-ready wet wipes, it’s essential to first outline the typical wet wipes production process.A typical wet wipes manufacturing process consists of the following four steps:

Wet Wipes Converting Process: Transform raw materials into the basic form of wet wipes.

Wet Wipes Packaging Process: Package the produced wet wipes.

Wet Wipes Lid Application Process: Apply lids to the packaged wet wipes.

End-of-the-Line Packaging Process: Final packaging, such as cartoning, for the packaged wet wipes.

Each step requires specialized machines, which work together to form a fully automated production line.

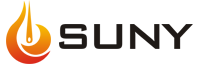

At SUNY Industrial, we manufacture fully automatic wet wipes production equipment. A complete automated production line typically covers the first three processes (the lid application process is optional). The full line includes:A Wet Wipes Converting Machine,A Wet Wipes Packaging Machine,A Wet Wipes Lid Applicator (optional)

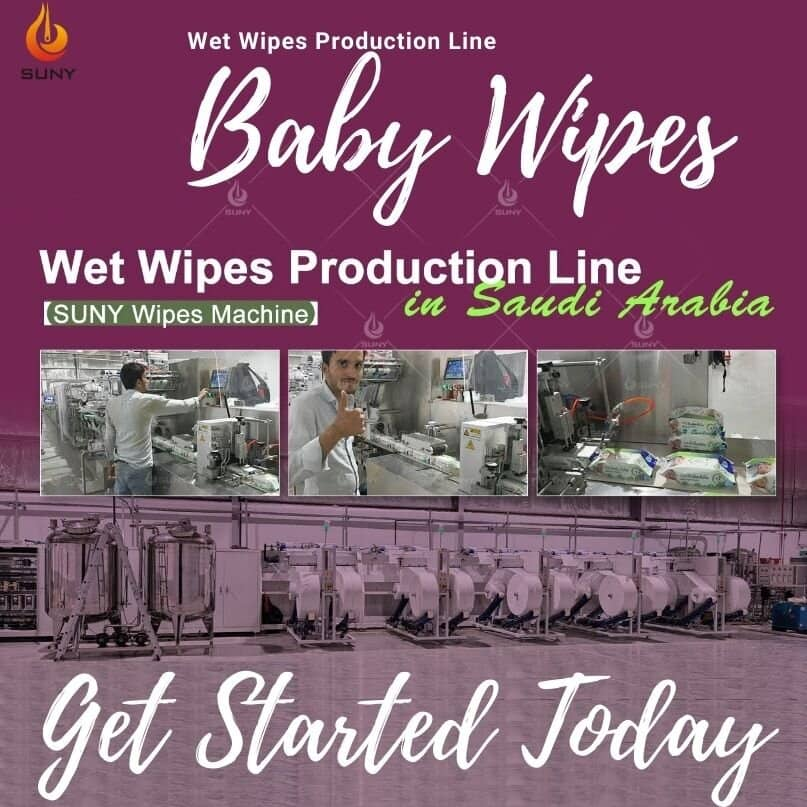

The End-of-the-Line Packaging System is an automatic case packer, operated by an 8-axis robot. This system picks up the packaged wet wipes from the primary packaging machine and packs them into cartons. If you prefer not to invest in a fully automated system right away, this step can also be done manually.

Contact Tel: +86 199 0388 6476

Contact Email: wipemachinery@gmail.com